WORDS: ELLIOTT HUGHES | PHOTOS: ASTON MARTIN

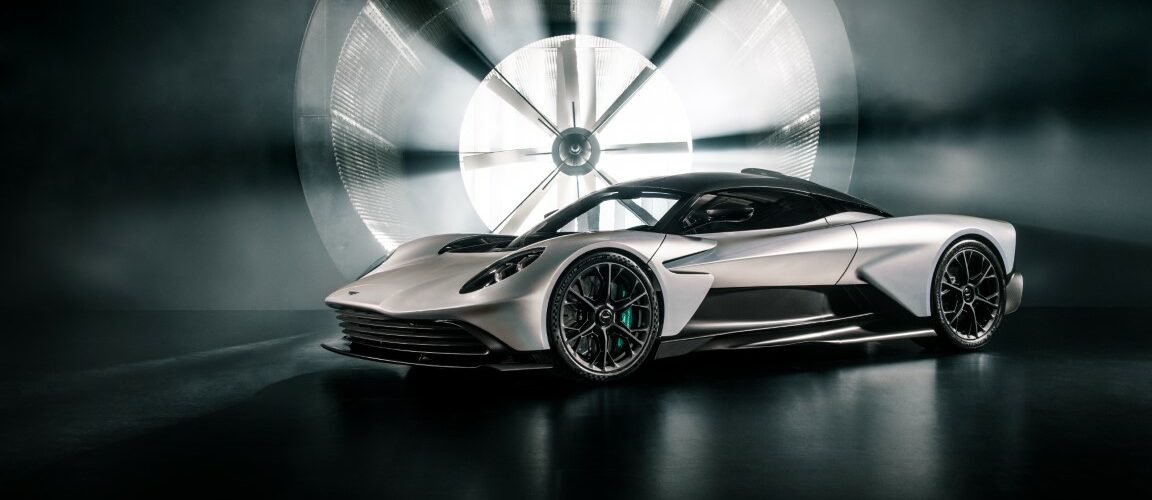

Aston Martin has revealed how its Formula 1 programme has influenced the development of its first series-production mid-engined supercar, the Valhalla, which is slated to enter manufacturing in 2024.

“Valhalla represents Aston Martin’s first joint development integration between our road-car engineers and Aston Martin Aramco Formula 1 team’s engineering capabilities,” explained global chief brand and commercial officer Marco Mattiacci.

Aston Martin Performance Technologies (AMPT), the marque’s technical consulting arm, is facilitating the road car and F1 division’s development of the Valhalla’s dynamics, materials and aerodynamics.

Alonso and Stroll’s input can be seen in the vehicle’s cockpit, which boasts an F1-inspired driving position

The use of simulation and CFD technology is a key area in which F1 know-how has been used in the Valhalla’s development. Aston Martin has revealed that more than 90 percent of the dynamic characteristics and vehicle set-up have been carried out in the simulator, while the final stages of development will be completed on road and track.

Assisting with the Valhalla’s development are F1 drivers Lance Stroll and Fernando Alonso, whose feedback is being used to hone the car’s dynamics and ergonomics.

Alonso and Stroll’s input can be seen in the vehicle’s cockpit, which boasts an F1-inspired driving position that features a reclined bucket seat and a raised pedal box. Aston Martin says that the driving position helps the driver feel connected to the car and allows for a lower roofline.

The Valhalla’s aerodynamic package has also benefited from F1 expertise. As with modern Grand Prix racers, the majority of the car’s downforce is generated via ground effects from the underbody. Complementing the underbody are multi-element wings front and rear, as well as slotted louvres on the sills that divert airflow from under the car to increase downforce.

Onboard computers dynamically adjust the attack angle of the car’s aerodynamic surfaces for minimal drag on the straights and maximum downforce in the corners – something that has long been banned in F1 with the exception of DRS.

Underpinning the Valhalla is a lightweight carbonfibre monocoque manufactured from a cutting-edge blend of carbonfibre materials. Resin Transfer Moulding (RTM) and an F1-spec autoclave are used to mould the upper and lower sections of the monocoque, creating a singular structure that is incredibly stiff, strong and light.

The powertrain pairs a bespoke flatplane twin-turbo V8 engine with three e-motors for a total output of 998bhp. The front wheels are driven by two of the e-motors, enabling torque vectoring and full four-wheel drive. The final e-motor is connected to the transmission, and works in conjunction with the V8 to drive the rear wheels. Aston Martin is yet to provide official performance figures.

The first running prototype will take to the road later this year, with the Valhalla set to enter production in 2024. Aston Martin will build 999 examples.