Words: David Lillywhite | Photography: Sam Chick

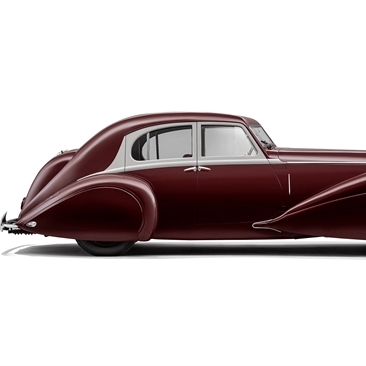

Even today’s Bentleys owe their styling to a couple of 1930s one-offs: the famous Embiricos and this, the Corniche, which has been completed in-house by the factory’s Mulliner division.

Bentley has a secret; it’s been a significant but largely forgotten part of the marque’s history since the late 1930s, never deliberately hidden but never actively publicised since things went disastrously wrong 80 years ago.

This is the Corniche, truly the missing link between vintage Bentleys of yore and the R Type Continental of the 1950s, which inspired the Continental GTs of today. Work on the prototype started in early 1939, but by mid-1940 the car had been largely destroyed through a series of misfortunes that you really couldn’t have made up.

Enough parts from the Corniche programme survived to inspire its resurrection, though. And it just so happened that the very first test drive of the recreated Corniche that you see here took place on July 10, 2019 – the 100th birthday of the Bentley marque.

We’ll return to this in a moment; you need the back story first…

The Corniche was born in a time when any Bentley sold in the UK absolutely had to be of the ‘English’ style – that is, with an upright radiator and huge headlights – despite that style seriously limiting top speed.

Meanwhile, there were a few crafty chaps who were less reverential, producing distinctly untraditional streamlined bodies. Dash them all! The most successful of these was the rakish 4¼ built for André Embiricos by the French Carrosserie Pourtout, to a design by Georges Paulin.

The Embiricos Bentley had been encouraged by renegade engineers at the marque keen to show the capabilities of their cars. It gained a creeping admiration from the more daring Bentley managers, nudged on by customer demand for faster, more sporting variants. However, it was uncomfortable by Bentley standards, and was based on a defunct model.

Bentley, having been rescued by Rolls-Royce and moved to that marque’s Derby factory in 1931, was set to introduce its new ‘rationalised range’ MkV saloon in late 1939. A proposal was made to also produce a lighter, more powerful version of the MkV, to be named the Corniche. Paulin was contracted to design a rakish, aerodynamic body, while the Bentley Experimental Department commissioned a thinner-gauge (0.092in instead of 0.128in) MkV chassis and higher-power engine.

By May 1939 Paulin’s design had been completed by French coachbuilder Vanvooren, and was shipped to England, arriving at the Experimental Department on June 7. Testing started within days, and at Brooklands on June 26 the Corniche achieved creditable 109mph and 111mph times on the flying mile.

It was then returned to France for high-speed testing from the company’s depot at Chateauroux, from where it was driven hard on French autoroutes and Italian autostradas. Initial faults logged included poor water sealing around the doors, inadequate cabin ventilation and a tendency for the engine to run hot – though not overheat – at high speed.

But in July, while being driven on the road by engineer Ivan Waller, the one-off Corniche was clipped by a bus. It was returned immediately to Vanvooren for repairs, and quickly collected again on August 8 by experienced test driver Percy Rose. Then, on the way back to Chateauroux, disaster struck! With the roads wet from a recent rainfall, a local driver pulled out in front of the Corniche. Rose swerved to miss the car, went off the road, hit a tree and rolled over. Body and chassis were badly damaged, although Rose got away with minor injuries (and a subsequent telling-off for driving too fast); a telegram was quickly sent to Derby to advise that the car’s testing was over for the foreseeable future.

Back at the factory, it had been planned that the Corniche would feature at the imminent Earls Court and Paris motor shows, alongside a standard-bodied MkV. A replacement chassis was quickly ordered, and the Corniche’s body removed from the damaged chassis to be repaired locally in Chateauroux rather than wait for Vanvooren. The chassis was transported back to Derby, arriving at the factory on August 16, where it was to be stripped and rebuilt onto its replacement.

But on September 3, war was declared. Within a day all car production at Bentley had ceased, and any works in progress moved into storage. At the Chateauroux body shop, repair work continued slowly, and it wasn’t until March 1940 that the body was completed and shipped to Dieppe, where cross-channel ferries were still operating despite the war.

Except, when the repaired body arrived at Dieppe, the RAC official responsible for export duties insisted that as the Corniche had passed through customs the previous year, then the repaired body constituted a second car, and must be taxed as such.

Bentley refused to pay, rightly pointing out that only the chassis had been shipped in 1939. In a Captain Mainwaring-like reply, the RAC claimed that: “Our men cannot have missed that there was no body, so there was!” While the dispute rumbled on, the body was stored in a warehouse at the Dieppe docks.

The story gets worse. At some point during the evacuation of Dunkirk, in late May or early June 1940, the Corniche was destroyed in a bombing raid. A memo to Bentley management from an RAC official asked where the keys for the car should be sent. The reply was apparently “robust”…

And that was the Corniche gone. Within two years, the great talent of Georges Paulin was lost, too, when he was executed along with master coachbuilder Jacques Kellner for working with the French resistance. The war also spelt the end of the MkV Bentley, with just 14 completed.

Eighty years on, and 100 years since WO Bentley formed the company, the Corniche is back, using a mix of original and re-made components. That it exists again at all is thanks to remarkable work by the Rolls-Royce Heritage Trust, coachbuilder Ashley & James, and the staff across all departments of Bentley Motors, particularly the Mulliner division. And, of course, the project started with a chance conversation, as these things so often do.

Former Bentley director, now automotive historian, Ken Lea takes up the story: “Sir Ralph Robins [then Rolls-Royce CEO] had a Derby Bentley that he raced, and which I helped look after. In 2001 he had a blown engine; he found a replacement but phoned me to say it didn’t fit. I said: ‘What’s the engine number?’ and realised it wasn’t a standard 4¼ [Derby Bentley], it was a MkV unit.

“That got us talking about the Corniche, and he was the one who persuaded the Rolls-Royce board that we should build a running chassis. I knew of a private individual with a lightweight chassis – it had been standing for years in tall grass so one side was badly corroded.”

There were three lightweight chassis made. One was the Corniche chassis damaged in the crash in France, and another was its intended replacement. Bentley Experimental Department chassis never received serial numbers, so there’s little way to know which one it is – but Ken is convinced that this was the original Corniche chassis. It appeared to have been stripped and used for testing, before being sold off by Rolls-Royce in 1971, as were so many spares at the time, including many MkV and Corniche parts that had been made ready for production.

So the project was off the ground, based at the Rolls-Royce Heritage Trust in Derby. A few invaluable drawings and technical specifications of the Corniche were sourced by the Sir Henry Royce Memorial Foundation and the Paulin family, and the few pictures existing of the car were forensically examined.

An engine was rebuilt to the Corniche specification, with high-compression pistons and larger carburettors and inlet manifold, and the chassis was slowly built up, as rare MkV and Corniche spares were further sourced.

The team of Rolls-Royce Heritage Trust volunteers, headed by Ken, progressed steadily with the project, with the Supermarine Spitfire team at the Trust joining in to create a new bulkhead from a single sheet of metal. However, by 2008 Rolls-Royce funding was drying up, so Bentley stepped in to help. A decision was then made to start on the bodywork alongside the chassis, rather than waiting for the chassis to be completed – a decision that Ken says saved the project.

Responsibility for the ash frame and bodywork was handed to coachbuilder Ashley & James, of Lymington, Hampshire. Ken worked with it to establish the structure of the body, of which there was no documentation – and even though funds dried up halfway through, the work continued whenever possible over the following eight years.

“I cannot over emphasise the contributions Ashley & James made to this project,” says Ken.

Back in February 2018, Adrian Hallmark joined Bentley as CEO, the successor to Wolfgang Dürheimer. He’d returned to Bentley after 13 years, and within days of arrival quizzed Robin Peel on projects that his Heritage department was involved with.

“Adrian made it clear that the Corniche was to come to Crewe,” remembers Robin. “He saw the significance of the car and what Bentley involvement would add to it.” But where would the Corniche be housed? A meeting was held between departments, with one of the attendees being Glyn Davies, special projects leader of the Mulliner bespoke division.

“I had no idea what this car was,” says Glyn, “but it sounded right up Mulliner’s street, so I stuck my hand up and said ‘we’ll take it’, and I’ve stayed with the project ever since.”

It helped that Glyn had previously worked with Ken Lea in the old Bentley Experimental Department during the late 1980s. He knew that many of the necessary coachbuilding skills were already a major part of Mulliner, which creates bespoke Bentleys to special order.

It was decided that the Corniche wouldn’t have an overall project leader, but that it would be run

by Robin, Glyn, Ken and Mulliner operations manager Ian Broomhall. They would meet every Tuesday evening to assess progress.

“My first impression was the time-scale,” recalls Ian. “How the hell were we going to do this! But it provided a fantastic opportunity for Mulliner to show the skills that we have here.”

The Corniche arrived in September 2018 on the assembled rolling chassis. After examination, it was moved from Mulliner to the Mulsanne build area at the top of the factory, where the body-in-white craftsmen would work on it in their spare time. By now it was autumn, and the team – including Adrian Hallmark – would traipse the length of the factory in the cold, wet and dark to work on the car or to receive weekly updates.

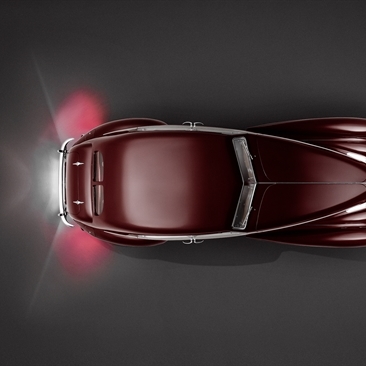

They’d often end up gathered around the front of the car, examining old pictures of the grille. This would prove to be the most challenging part of the project for Mulliner; work was needed on the amount of cooling air through the grille, plus it was clear from the pictures that, as a prototype, there were uneven gaps between the vanes of the Corniche’s grille. Adrian Hallmark made it very clear that the recreated item would need to be to a higher standard.

“We scanned the vehicle’s nose and apertures in the body, and did a bit of reverse engineering in CAD,” says Glyn. “Then we would cross reference with the original photo, comparing it with the CAD model. The styling department’s modellers supported the project by producing a pair of vane-assembly tools in their own time, machined in Ureol, to help create each vane and its positioning. Each one was individually designed in CAD, computer analysed for airflow, then painstakingly hand formed in three planes. The car was with Mulliner for six months, and the vanes were only screwed into place on the last day.”

Meanwhile, work on the bodywork continued, particularly on devising better sealing for the doors. Working alongside Ken, Mulliner coachbuilders Nick Chandler, Kev Foster and Ian Williams completed the finishing touches for the body.

Then the question came up of paint choice. The body colour was well documented as French Garnet, but as for the side strip…

“The reports said ‘pinky grey’; we really couldn’t understand that,” says Ken. “But we also knew that the Corniche had a West of England cloth headliner, and when we found a roll of that we realised it had a pink tinge.”

“It still took three months, and dozens and dozens of varying paint samples, to get right,” recalls Glyn. “Sample after sample was rejected by the steering group, but the Bentley paint team, led by Rob Thompson, stuck with us, using spectral analysis to analyse the colour and finally formulate the new Heather Grey, which looks exactly right. The red formulation was named as Imperial Maroon.”

In parallel with the trials and tribulations of the bodywork and paint, there was also the interior to finish. Trouble was, there were no full pictures of the interior.

So, what to do?

Bentley head of interior design Darren Day, and his team Louise McCallum and Frederic Dams, worked with Ken to translate his research into 2D styling images. Ken had examined Vanvooren styles, descriptions from Corniche documentation and the glimpses of interior visible through the windows in exterior photos. The resultant artwork helped Mulliner’s coachbuilders to visualise what they needed to create.

Rolls-Royce specialist The Real Car Co. in Wales had donated many Vanvooren parts early on in the project’s life, including original Vanvooren seats. In their spare time, the design team used all this to design upholstery patterns that are thought to be as close to the original as is possible.

Jonathan Connolly visited from Connolly Leather, and he helped specify the authentic Connolly Vaumol hide in a colour that worked with the exterior. The seats themselves had to be made first, though, adapting a MkVI rear cushion and the donated Vanvooren parts. The first step was to strip down the tatty Vanvooren rear seat to examine its construction.

“It was a like a cartoon,” laughs Robin. “As the sackcloth came off the springs burst out, and the horsehair went everywhere!” The trim-development department managed to source horsehair and the correct style of sackcloth and twine, and the Mulliner team had the springs remade.

The dashboard was assembled using the correct Bentley MkV instrumentation and switchgear. The door handles and window winders had been cast specifically for the Corniche, in Vanvooren style, by Ashley & James.

Then there were the wooden window surrounds to create… These were the job of Mulliner master carpenter Gary Bedson, who created a steam box to bend the wood to the curves of the windows (and note just how curved the rear edges of the rear door windows are). It was a slow process, with Gary sometimes disappearing in a cloud of steam for an hour for just one degree more of curve, but the end result is quite remarkable.

An important aspect of the project was that apprentices were involved, too, as part of the programme of passing down coachbuilding schemes to a new generation. A tool tray, carrying genuine tools collected by Ken, was created by Nathan Betteley to sit in the boot; Brad Horton assisted Dave Latham on the electrics; Dominic Grimshaw was involved with the sheet metalwork; Jack Edwards made use of his coachbuilding skills and Terry Feeley helped with trim.

One of the few parts that there were no drawings for was the exhaust. A picture had been taken of the car post accident, when it tipped on its side, giving a clear view of the original exhaust layout. Of course, there’s an argument that if there hadn’t been an accident, there wouldn’t have been any need to recreate the Corniche, but…

Anyway, yet more tricky bits; the headlamp assemblies were unique, and the originals were never, ever tracked down. The headlamp cans had been hand formed in brass by Ashley & James, and the Mulliner team had them silvered in the Birmingham jewellery quarter. After weeks of research, a glass maker was persuaded to produce the lenses.

Thankfully the window glass was easier, made from plywood patterns by GKN Aerospace – formerly Pilkington and before that Triplex, who had produced the original glass.

The original Corniche had never quite been completely finished, so the pictures of the car in testing show crude bumpers and different rear lights from those specified by Paulin. It was decided to complete the car to its intended production specification, going by Paulin’s design sketches – and that’s how you see it on these pages, ready for a new life on the Bentley Heritage fleet.

“We’ll use it as an important piece of our history; it will travel the world,” Robin confirms. “It will be used in the appropriate fashion at events and rallies, relevant to the Bentley marque.”

How appropriate, then, was that centenary day first drive – and equally appropriate that it should be Ken behind the wheel, giving other members of the team passenger rides.

“It was a delight to drive,” he says, “but Mk5s are a delight because they ride so well on their long wheelbase. The vision is stunning, it doesn’t give a pillbox effect from inside, and the engine and gearbox were even better than expected. We all stood back at the end of it; we couldn’t quite believe we’d done it!”

The Corniche is likely to appear first at a UK event in September. As for the Mulliner team, can we expect more classic Bentley projects from the crew in the future after the success of the Corniche? Don’t rule anything out…

If you liked this, then why not subscribe to Magneto magazine today?